Home > Automotive Electronics

Inline PCB Router-CNC PCB Router Depaneling Machine,SMTfly-F03

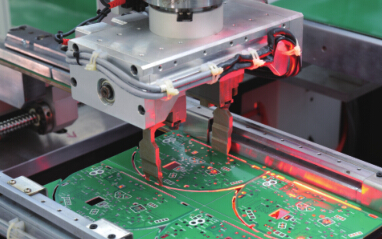

An on-line PCB which is specially used to cut PCBA components(panel) into separate parts, featuring rail-mounted structure without jig cutting. It can be put into production immediately. Featuring ESD static monitoring, cutting stress feedback, and automatic tool changing, it can reach a top speed of 60000 rotates. The control system developed on the basis of our RM system can ensure customer’s rapid and accurate programming.

Specification:

|

Model |

SMTfly-F03 |

|

Machine Size |

1000*1200*1533mm |

|

Weight |

Approx 1900kgs |

|

Max PCB Size |

350*350mm |

|

PCB Thickness |

0.4-6mm |

|

Transmission height |

900±50mm |

|

Transmission direction |

Left -> Right |

|

Transmission speed |

1500mm/s(max)/adjustable |

|

Feeding plate type |

Section-type transportation guide rail |

|

Rail width adjustment |

Automatic |

|

Communication signal of upper and lower computers |

SMEMA |

|

PCB Positioning |

Upper and lower guide rail clamping |

|

Picking system |

360°rotary clamping system; 2 groups of vacuum suction nozzles at most, 4 groups of ESD belt transportation/batch panel forwarding units at most |

|

Cutting spindl/speed |

Germany KAVO, 60,000rpm/min |

|

Cooling type |

Air compression |

|

ESD monitoring |

Yes |

|

Automatic tool change |

Yes |

|

Cutting stress feedback |

Yes |

|

Break blade check |

Yes |

|

Cutting speed |

1-200mm/s |

|

Cutting accuracy |

±0.5mm |

|

Repeat positioning accuracy |

±0.01mm |

|

Coordinate moving speed |

1000mm/s |

|

Out plate type |

ESD belt transportation/batch panel forwarding unit |

|

Waste collection type |

Out off the track |

|

Procedure programming |

GERBER drawing import/Editing program through visual system |

|

Air supply |

5-8kg/cm2 |

|

Power supply |

AC380V±5%, 50/60Hz, 3KW |

Features:

1. Automatic tool change

2. ESD monitoring

3. Cutting stess feedback

4. Automatic production mode

5. Linkage between Spc statistic

functionand customer’s

management system-ERP

6. Can be equipped with explosion-proof function of vacuum cleaner

High reliability cutting system

Germany KAVO high-speed principal axis with a top

speed of 60000 rotates, featuring ESD static voltage monitoring and the

functions of cutting stress feedback and automatic tool changing.

Super Vision System

A precise machine visual system which consists of German imagining industrial camera, Moritex Lens and measurement-level light source; it

supports all functions of machine calibration, compensation and positioning, featuring highstablility and anti-disturbance capacity.

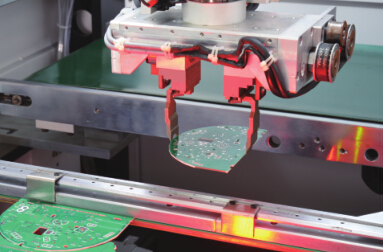

High reliability PCB gripper system

A perfect solution without jig cutting; A PCB clamping size scope of 2mm, the pick up device can realize repid loading/uploading, featuring high stability and low cost.

Automatic tool changer

The standard tool changer supports three kinds of 3.175mm tools, each of which has a top loading Capacity of 10 ones. It is combined with precise clamping system and lifting system; three axes -X1,Y1 and Z1 of the cutting mechanism can realize tool changing.

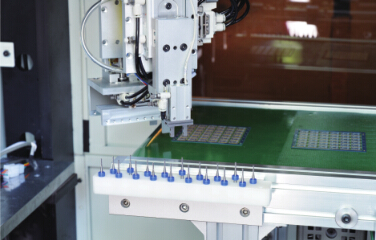

Panel forwarding solution 1: the cut PCB will be

delivered by clamping system to belt transmission line, and then sent by ESD

transmission line via machine into assembling line, or be picked up and loaded

into product case by customized manipulator solution.

Panel forwrding solution 2: use batch panel forwarding unit ARM-1 dismantle belt transmission line from machine, insert panel forwarding unit from behind the machine, and directly load the panel into blister box in ARM-1 via clamping system. The solution is featured By simplicity and convenience.

Contact: Bunny

Phone: /Wechat/Whatapp: + 86 136 8490 4990

Tel: 0769-82784046

Email: s5@smtfly.com

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, China 518103